Hydraulic testing Laboratory

Hydraulic testing Laboratory was established in March 1972 and it has grown into one of the largest suppliers of standard and specialty fittings in the world. The test of products can satisfy the application in military aerospace, commercial aerospace, marine and nuclear markets. As the same time, the laboratory issues the test report (FAA、CAA) by authority. Our goal is to supply our customers with economical, high-effective product testing and issue the test report and certificate.

Technical staff consists of:

• Research, Design and Development Engineers

• Computer Assisted Design (3D CAD SolidWorks) Draftspersons

• Laboratory Test Engineers

• Laboratory Technicians

Unique technical abilities consists of:

• Application Design

• Product Design

• Installation Tool Design

• Gage Design

• Feasibility Studies

• Qualification Testing Programs

• Post-manufacturing Functional Testing Programs

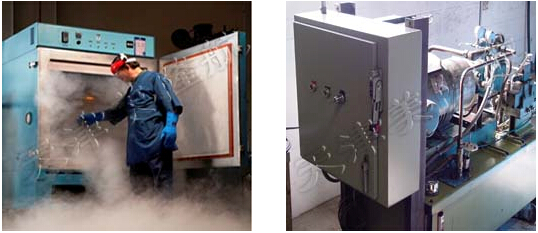

Hydraulic testing Laboratory is a fully functional Hydro-Mechanical test facility, providing qualification, verification and performance testing of fittings, tube assemblies and hydraulic components.

In addition to standardized hydraulic testing, our staff of experienced engineers and technicians can provide guidance for product design and evaluation, detailed test plans, procedures and formal test reports, all of which can be specifically tailored to your applications.

Test projects:

• Damped wave impulse test per ARP 603

• Sine wave impulse test per AS4265

• Square wave impulse testing

• Flexure fatigue test per ARP 1185 and ISO 7275

• Hydrostatic pressure test (proof and burst)

• Water pressure test

• Pneumatic pressure test with nitrogen

• Salt spray aging

• Stress Corrosion

• Tensile testing of tube fitting assemblies

• Repeated assembly

• Helium leak detection.

Both Impulse and Flexure tests can be conducted at temperatures ranging form -100˚ F to +350˚ F.

Test report:

The “Product” is the test report which outlines the methods used and the results obtained for the products, assemblies, or systems tested.

Since its inception in 1972 Hydraulic testing Laboratory has conducted test programs for major aerospace companies such as:

If you need relevant testing or certification, welcome to contact with Tianjin Melongtech. We have experienced engineers to provide you with a full range of professional solutions.

客服1

客服1