SMA

Many metals exhibit a phase change as they are heated and cooled. We can illustrate this using a crude ‘stick and ball’ model of the metallic lattice. The phase change is an instantaneous shear transformation between a body centered cubic structure called austenite and a highly twinned martensite structure. Shape Memory Alloys are a special class of alloys which not only change phase on cooling or heating but have the particular characteristic of a low temperature phase which gives the appearance of increased ductility.

The higher temperature austenitic structure has the characteristic stress strain curve of most metals.

The lower temperature martensitic structure has a stress strain curve more like that of an elastomer in which there is a ‘plateau’ stress.

All the deformation up to about 8% is “elastic” or in other words it can be recovered but not by simply relaxing the stress while in the martensitic condition.

Let’s go back to the ‘stick and ball’ model. We cool the material and it becomes martensitic. It does not change shape by being cooled, but we can now deform it mechanically. If it stays cold it will remain deformed, but if we allow it to warm up, the austenitic structure reappears and the material returns to its original shape.

This cycle from austenitic to martensitic to deformed martensitic and back to austenitic is repeatable indefinitely and is what we call ‘free recovery‘. It is important to note that it is a one way process.

SMA Fittings Benefits

• The shape memory alloys can be installed with a variety of pipe materials including

• No leaks, The SMA systems have an outstanding record of over 39 years of leak free performance. During constrained recovery the alloy develops considerable force and effectively “self swages” the sleeve permanently onto the tube.

• If the tube cannot pass though the coupling, the coupling should be removed from stock and returned for re-expansion.

• The total cost of nickel-titanium alloys is cheaper than ordinary pipe fittings.

• No expensive tooling, the installation tools are gloves, tube chiller, marking pen and so on.

• The installer needs only his/her hand, which allows for simple installation in any area accessible by the installers' fingers.

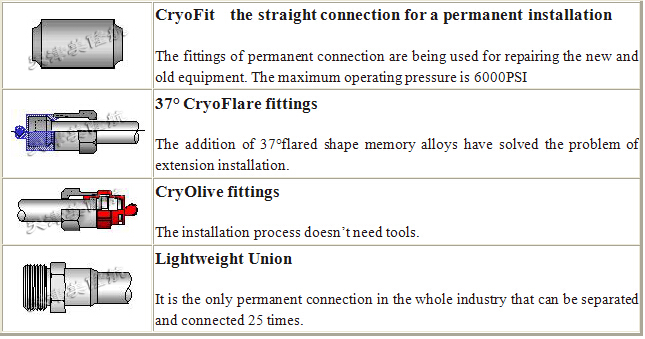

The shape memory alloys classification

The range of Shape Memory Alloy fittings now extends to cover a full range of parts for system pressures up to 5000psi and beyond. Permanent and separable couplings for both metric and imperial sizes are available.

Main Customer:

Boeing,Airbus,Douglas、Canadair、Bombardier、Cessna、Raytheon、United、Northwest、Air Canada、Alaska、Air France、Lockheed Martin、Hughes、Primex、Matra-Marconi、DASA-RI

客服1

客服1